Home / ESG / Sustainable Supply Chain

Supply Chain Management

RichWave is a professional chip R&D company that does not engage in large-scale production. All product raw material procurement, wafer fabrication, packaging, and testing are carried out by our suppliers and partners. Since the raw material sourcing, design and manufacturing, and transportation stages of the product life cycle are all closely related to the supply chain, in order to avoid negative impacts on society and the environment, we are committed to cooperating with our suppliers. Through new supplier selection, existing supplier evaluation and auditing, we strictly require suppliers to comply with the local economic, environmental, and labor laws and regulations, fulfill their social and environmental responsibilities, and prohibit the use of conflict minerals, as well as to implement energy-saving, emission reduction, and pollution prevention to form a sustainable supply chain for RichWave products.

Upstream, Midstream, and Downstream Industrial Chain Relationship

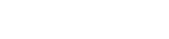

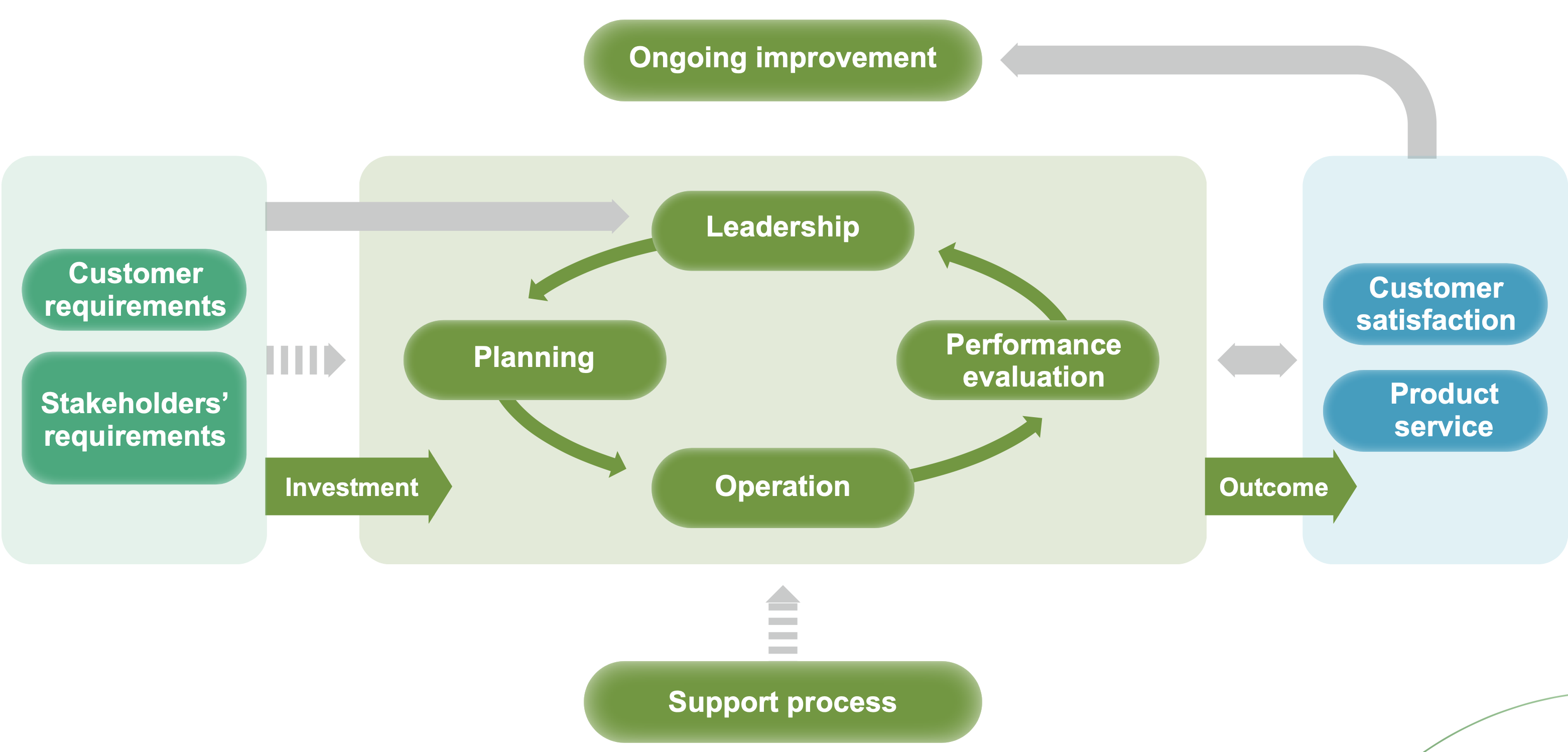

RichWave products and services comply with the ISO9001 / ISO14001 quality/environmental quality management system standards from order taking, design and development, purchasing, manufacturing, quality control, packaging and delivery of finished products to after-sales services. Our operations are centered on the manufacturing and sale of established or customized products, and we control all the main processes and sub-processes related to the manufacturing and sale of products. From the communication of customer requirements, production, delivery of finished products, to the continuous improvement of processes and products, we follow international standards and regulations, and we continuously monitor and review the information of the above internal and external factors.

Responsible Supply Chain

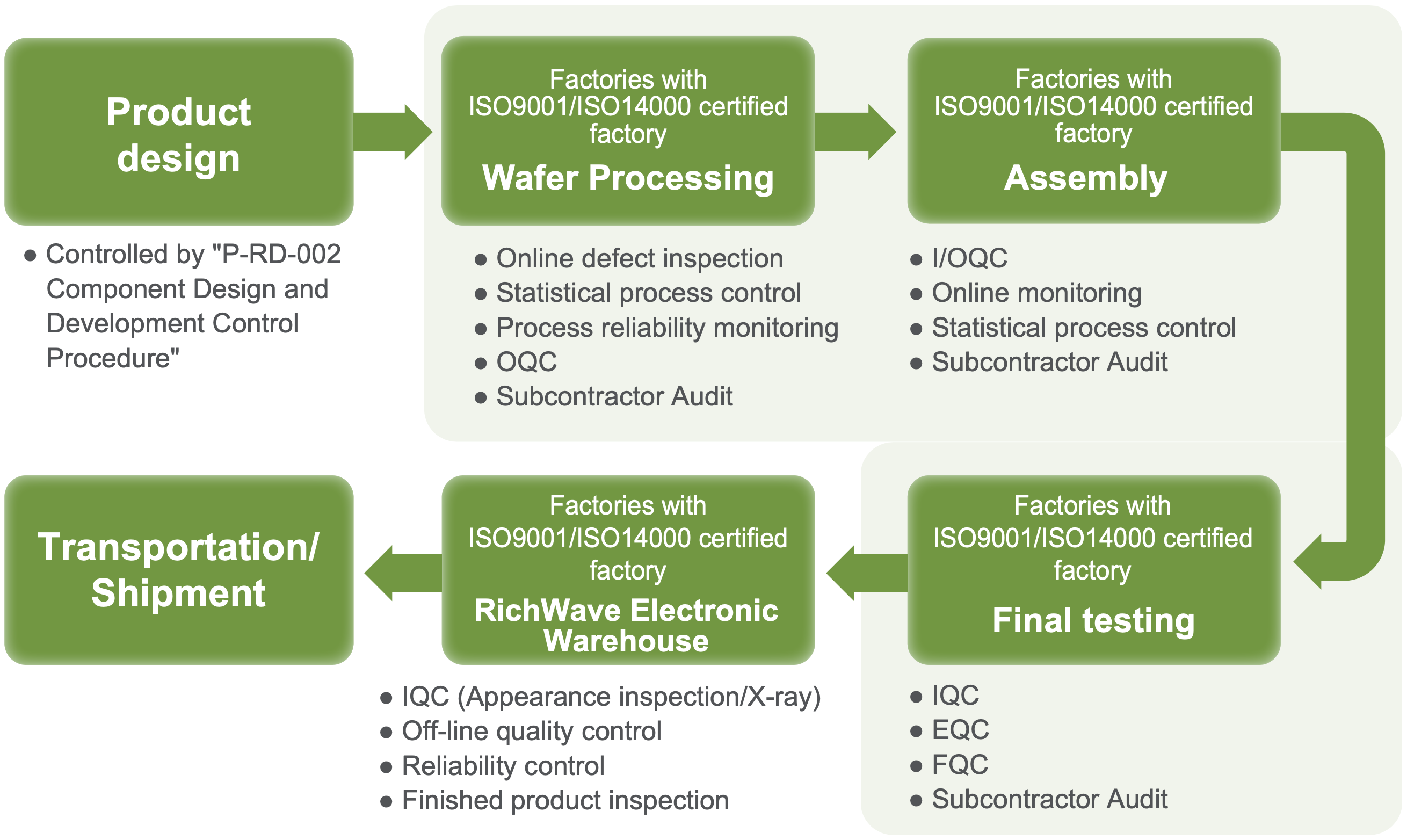

To mitigate the product value chain's negative impact on the local environment and society, as well as to effectively manage potential risks, RichWave has created a QA Department to supervise suppliers' legal compliance in aspects such as environment, occupational safety, and health or labor rights, as well as to ensure the fulfillment of corporate social responsibilities. We have established a comprehensive supplier management process, where the screening stage of new suppliers involves a detailed review of their corporate social responsibility performance; apart from reviewing their engineering capabilities, we also demand our suppliers provide international quality certification, request a declaration that they do not use any hazardous substance, and complete the conflict minerals investigation before they can be registered as RichWave's suppliers.

In terms of existing suppliers, we carry out regular supplier evaluations and supplier audits every year. In addition to evaluating the quality and reliability of suppliers, we also incorporate ESG-related scores into our supplier audits. For suppliers with scores below the required level, we will provide counseling to improve the situation, and if the results of the re-evaluation and tracking results still fail to meet the standards, we will stop purchasing or cancel the qualification of the suppliers. In 2023, we conducted audits on 20 of our main suppliers across three major categories (wafer, packaging, and testing), achieving an audit coverage rate of 100%, and no suppliers exhibited negative ESG impacts.

Furthermore, we convene quarterly supplier meetings to exchange quality, construction, delivery, and production capacity-related opinions with our suppliers, as well as share experiences and reach a consensus in the field of sustainability for the sake of forging a long-term, stable partnership and bolstering the sustainability of the supply chain.

RichWave's Supplier Management Process

RichWave's Supplier ESG Audit Plan

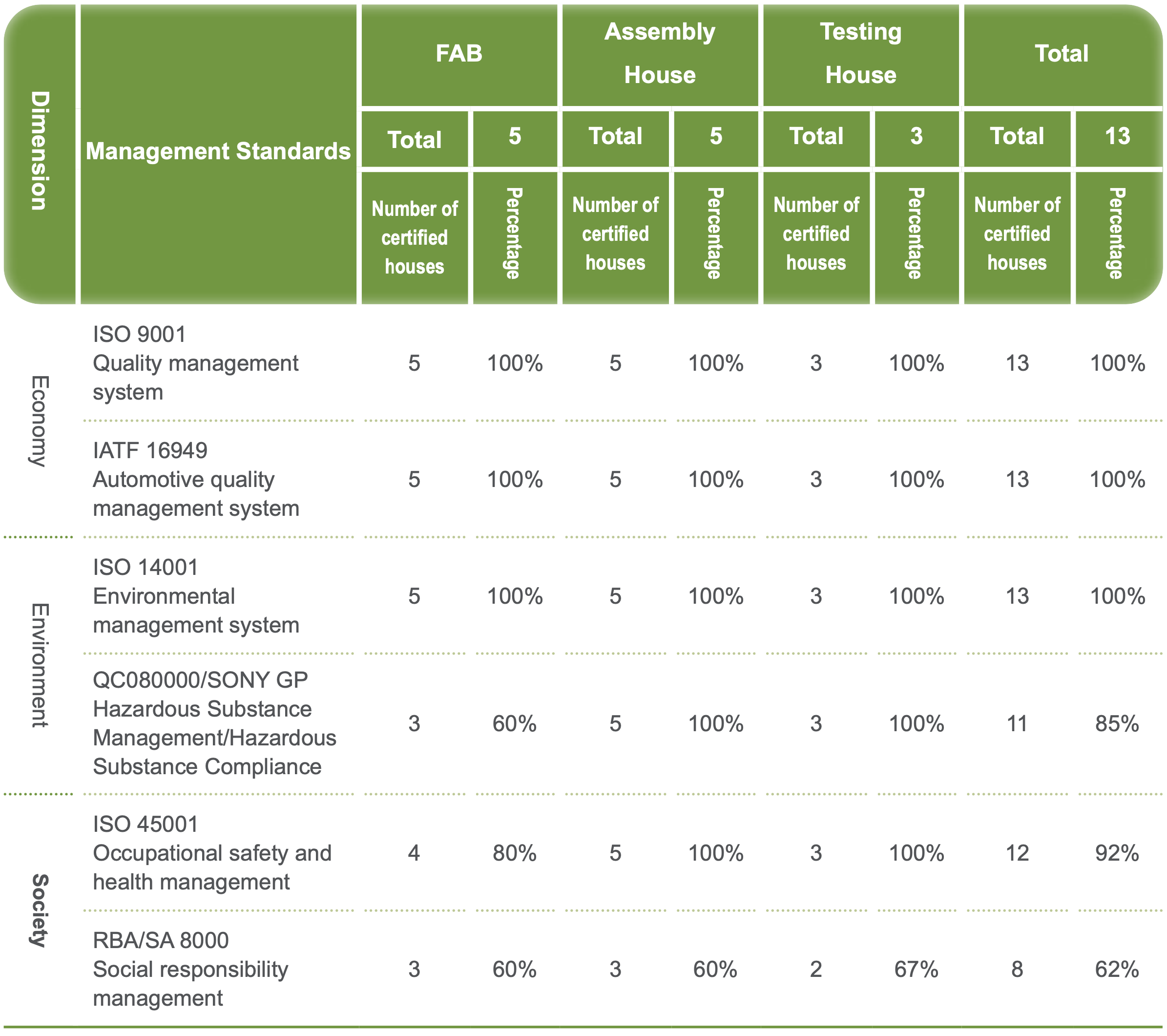

Certification Statistics of Suppliers

Compared to 2022, one Assembly House and one FAB House received the RBA/SA 8000 Social Responsibility Management System certification in 2023. In addition, all 13 major suppliers of RichWave obtained ISO 9001 Quality Management System, IATF 16949 Automotive Quality Management System, and ISO 14001 Environmental Management System certifications. Other certification projects are being acquired based on the individual suppliers' schedules.

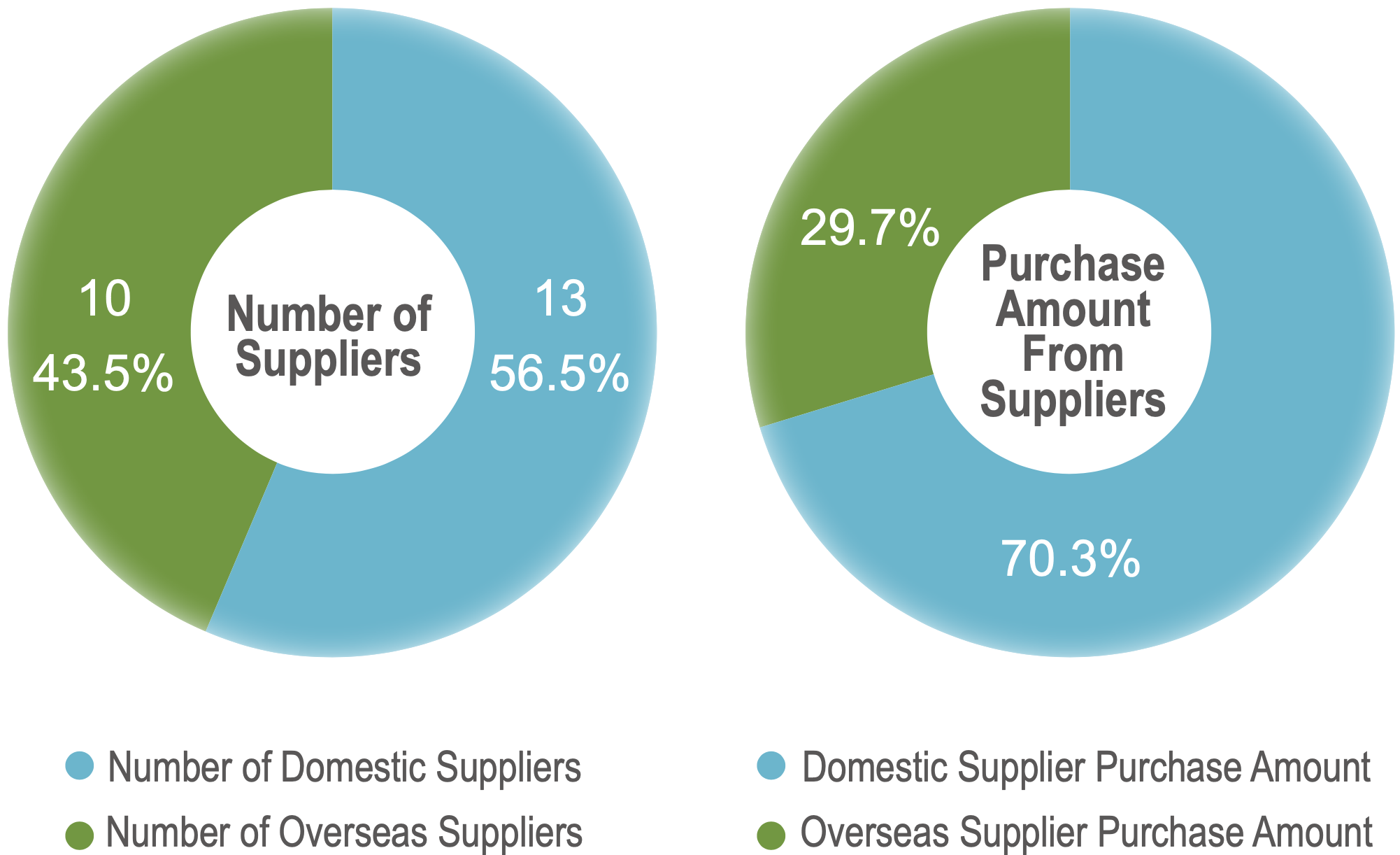

Local Procurement

RichWave understands that transportation of raw materials is an important aspect of greenhouse gas emissions during the product life cycle, hence we have vigorously advocated the local procurement policy, which involves prioritizing local suppliers when making purchases. In 2023, RichWave's procurements from domestic suppliers account for 70.3% of our total procurement amount. In the future, we will continue to implement local procurement on the premise of prompt delivery and lowering supply risks; besides decreasing transport-related carbon emissions and costs, we can also foster developments in the domestic industry and reduce our reliance on foreign manufacturers.

RichWave's Local Procurement Ration in 2023

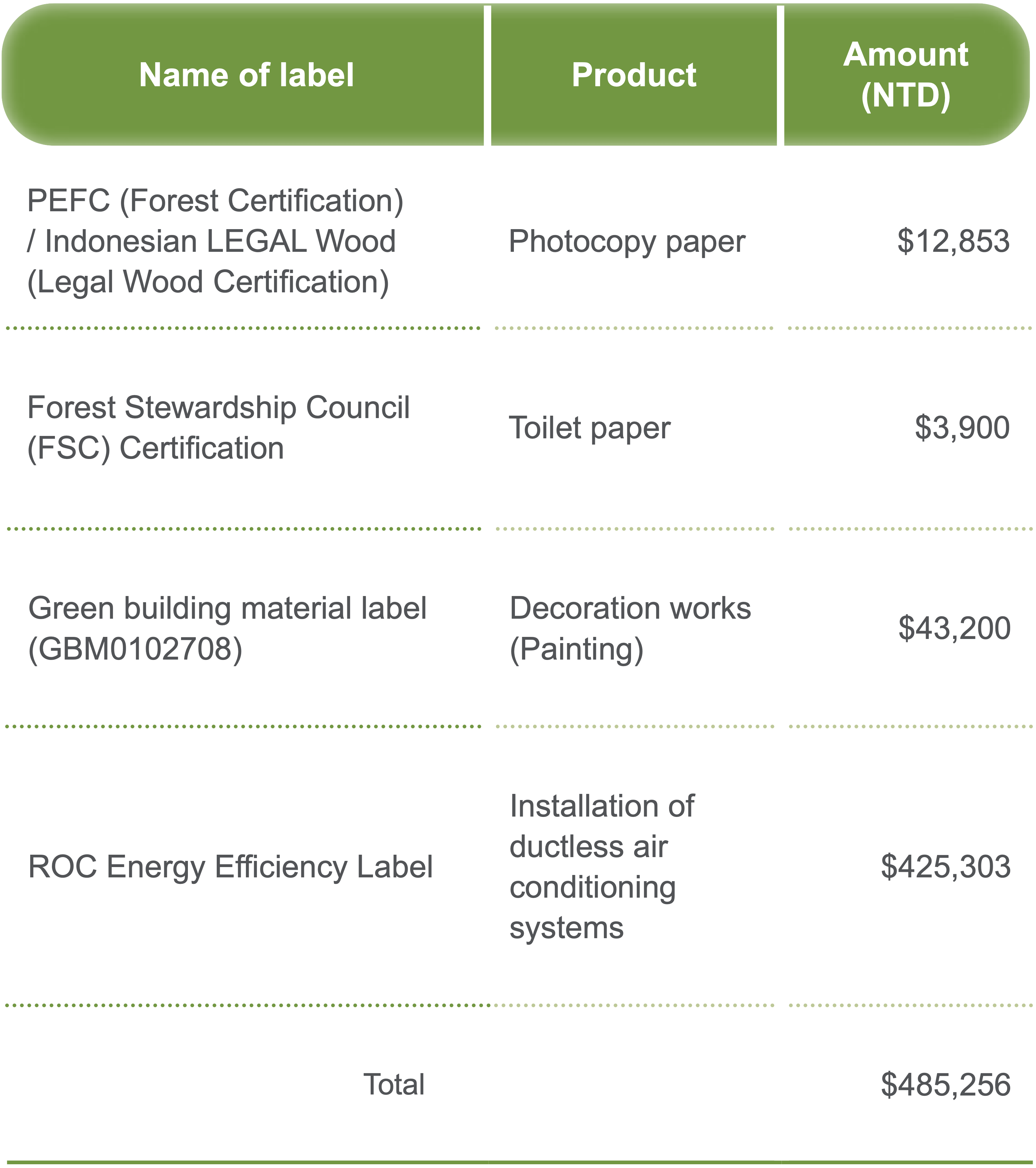

Green Procurement

Green consumption has become an international trend; thus, consumers and enterprises are leaning toward green products and services. At RichWave, we have internalized the concept of environmental sustainability into our procurement policy by choosing products that comply with green and environmental regulations including domestic/overseas environmental labels, energy-saving labels, carbon footprint labels, carbon reduction labels, Energy Star, FSC, and PEFC sustainable forest labels. While mitigating the environmental impact of our operations, the company also benefits from decreased energy expenditures, thus we will continue to materialize green procurement to support the development of green products and industries through tangible actions.

RichWave Technology's 2023 Purchases of Products with the Green International Labels

Raw Material Management

Chemical Substance Management

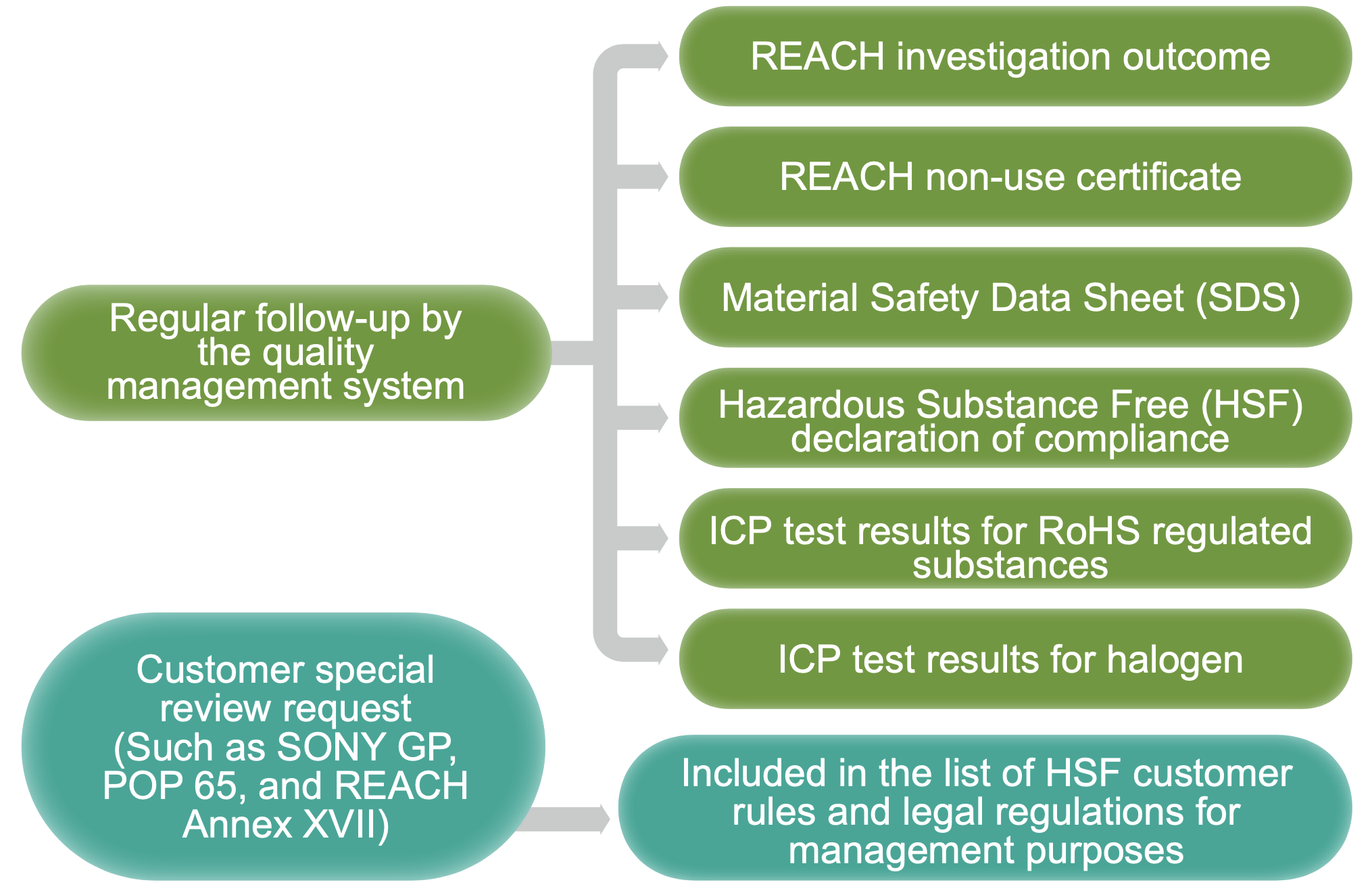

RichWave sees maintaining customers' health and safety and protecting the natural environment as our responsibility. We have not only obtained ISO 9001:2015 certification and maintained IECQ QC080000 compliance but also the SONY GP (Green Partner) and Samsung Eco-Partner certification by rigorously controlling the chemical substances of our raw materials. To ensure the safety and eco-friendliness of our products, we have stipulated the environmental substance control protocol, demanding our primary suppliers to respond to the survey results after the biannual EU REACH dossier updates are published, and all the suppliers must provide a REACH certificate of non-use, Safety Data Sheet (SDS), and Hazardous Substance Free (HSF) declaration of compliance. The finished ICs will be sent to a third-party certification organization for hazardous substance testing every year, and 100% of the finished ICs were RoHS compliant and halogen-free in 2023. In addition, all suppliers are required to provide third-party testing ICP reports within one year to RichWave for systematic management, and the reports must contain at least 10 items of RoHS and halogen (for organic substances) test results. In 2023, the third-party test reports of all raw materials were all updated and the compliance rate was 100%. For other special requirements from our customers including SONY GP, POP 65, and REACH Annex XVII, we will conduct individual reviews and include them in the list of HSF customer rules and legal regulations for management purposes.

RichWave sees maintaining customers' health and safety and protecting the natural environment as our responsibility. We have not only obtained ISO 9001:2015 certification and maintained IECQ QC080000 compliance but also the SONY GP (Green Partner) and Samsung Eco-Partner certification by rigorously controlling the chemical substances of our raw materials. To ensure the safety and eco-friendliness of our products, we have stipulated the environmental substance control protocol, demanding our primary suppliers to respond to the survey results after the biannual EU REACH dossier updates are published, and all the suppliers must provide a REACH certificate of non-use, Safety Data Sheet (SDS), and Hazardous Substance Free (HSF) declaration of compliance. The finished ICs will be sent to a third-party certification organization for hazardous substance testing every year, and 100% of the finished ICs were RoHS compliant and halogen-free in 2023. In addition, all suppliers are required to provide third-party testing ICP reports within one year to RichWave for systematic management, and the reports must contain at least 10 items of RoHS and halogen (for organic substances) test results. In 2023, the third-party test reports of all raw materials were all updated and the compliance rate was 100%. For other special requirements from our customers including SONY GP, POP 65, and REACH Annex XVII, we will conduct individual reviews and include them in the list of HSF customer rules and legal regulations for management purposes.

RichWave's Quality Management Process

In 2023, RichWave has confirmed that 100% of our materials comply with RoHS, halogen-free, and REACH requirements through the quality management system, and there were no product and service-related health and safety violations. Furthermore, we have included the RoHS, Lead- Free, and Halogen-Free labels on the products' external packaging and product specifications, and third-party ICP test reports for various materials are provided based on the product model number so that consumers can prevent hazardous substances from endangering people's health and the surrounding environment while enjoying convenience made possible by modern technology.

RichWave's Chemical Substance Management Framework

Overview of Green Product Certifications and Labels Obtained by RichWave

RichWave's products have obtained RoHS, Lead-Free, and Halogen- Free labels

Key Raw Material Management

RichWave defines raw materials with high procurement amounts as critical raw materials. In 2023, wafers accounted for 51% of the total raw material procurement amount, which is regarded as RichWave's critical raw materials. To ensure a stable and continuous supply of critical raw materials, 2 or more foundries are engaged for the same type of wafer manufacturing process (e.g., GaAs/SOI, etc.) so that production risk is minimized by avoiding the impact of sudden climate accidents, material shortages, transportation delays, and other factors on the production of products.

Conflict Mineral Management

Conflict minerals such as tantalum, tin, gold, and tungsten are obtained from the DRC that are often associated with armed conflicts, endangerment of the local environment, and human rights. Since tantalum, tin, gold, and tungsten are important raw materials in the manufacturing of electronic products, how to prevent human rights violations and environmental damages resulting from the purchase of conflict minerals has become a key challenge for the management of the electronic product supply chain.

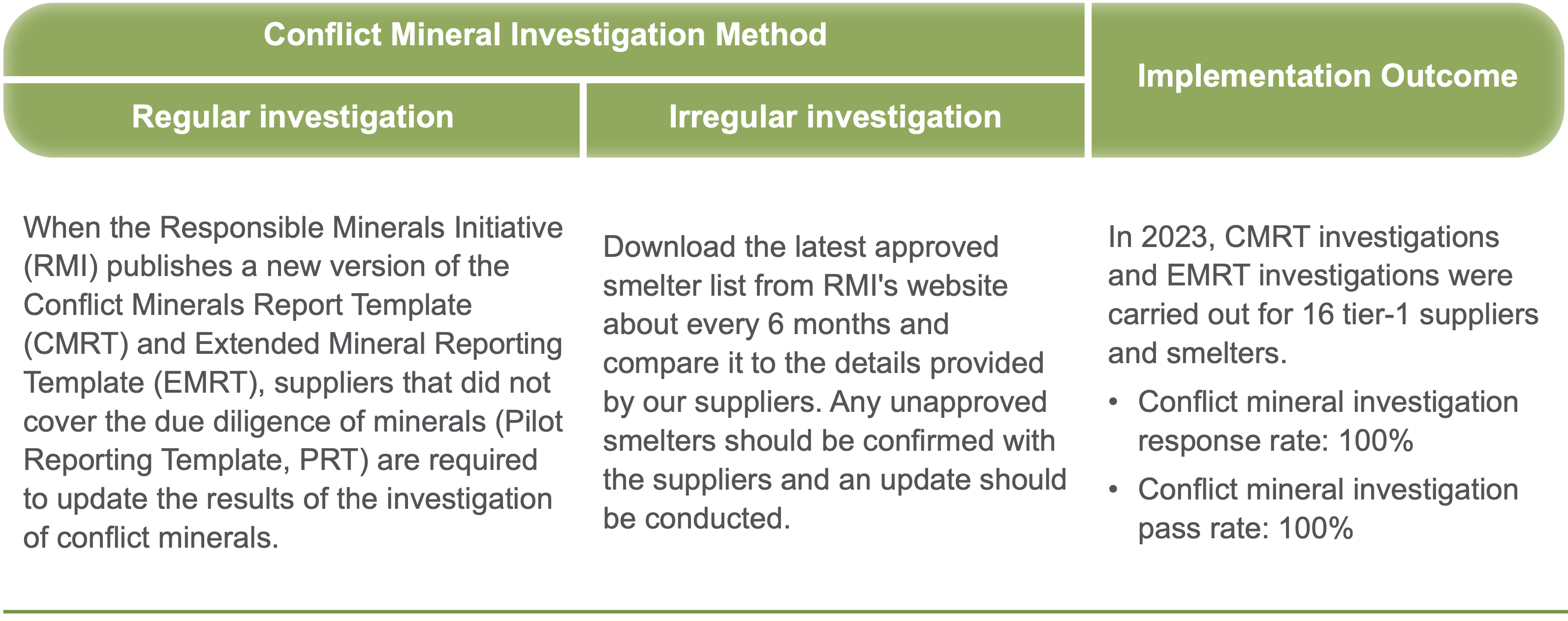

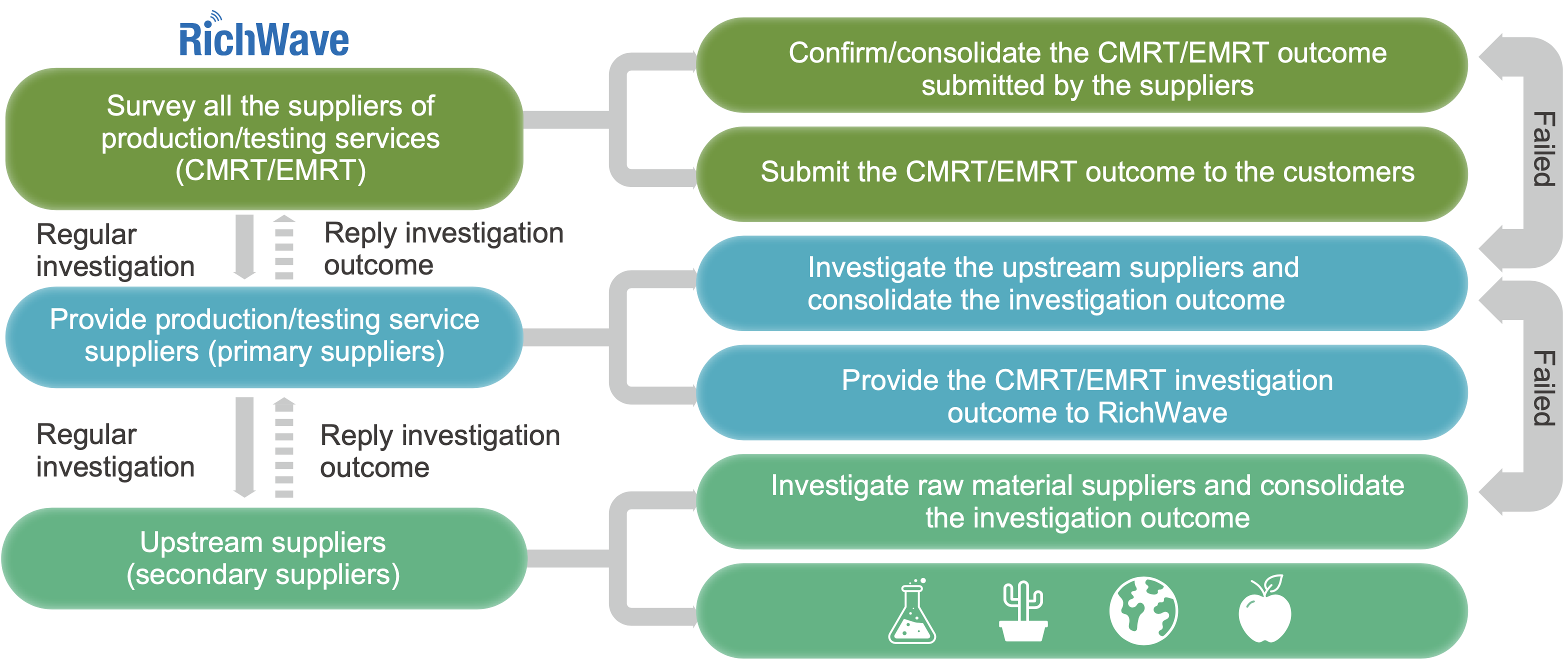

RichWave has specified in its Environmental Substance Management procedures the conflict minerals control requirements that suppliers need to follow. We have prohibited our suppliers from using conflict minerals (including tantalum, tin, gold, tungsten, and other minerals or derivatives from the DRC and surrounding countries/regions that are deemed to have been associated with sponsoring armed conflicts in the said countries/regions. In addition, we have also established a comprehensive conflict mineral management process to conduct conflict mineral investigations on our primary and secondary suppliers. The system is used to identify and adequately control conflict mineral-related risks.

RichWave's Conflict Mineral Management Process

Implementation Status of RichWave's Conflict Mineral Investigation